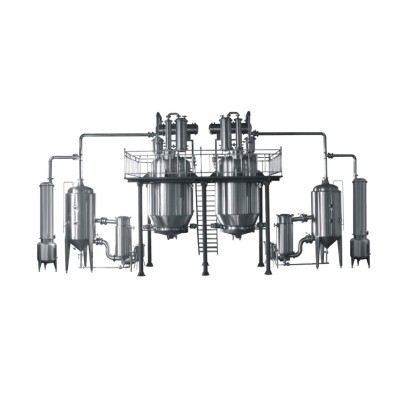

LTN-10/4000 High Efficiency Low Temperature Extraction and Concentration Production Line

LTN-10/4000 High Efficiency Low Temperature Extraction and Concentration Production Line

| Categories | Extracting and Concentrating Machine |

|---|---|

| Brand | LTPM CHINA |

| Model | LTN-10/4000 |

| Model | LTN10/4000 |

| The volume of extracting (m³) | 10 |

| Concentrating quantity(kg/h) | 4000 |

| Raw Material Input Capacity (kg) | 1000-1300 |

| Capacity of Concentrating Evaporator | 4000kg/hour |

| Water Circulation Capacity | 300-400T |

| The time of extraction (h) | 8 |

| Concentrate density (%) | 1.2-1.35 |

| The work temperature of extracting and concentrati | Water: 50-90°C Alcohol: 40-80°C |

| Power of Vacuum Pump | 37kw |

| Unit Price | US $ 37000 / piece |

| FOB port | Ningbo |

| Terms of Payment | L/C, D/A, D/P, Western Union, MoneyGram, T/T, Paypal |

| Update Time | Apr 17,2025 |

LTN-10/4000 High Efficiency Low Temperature Extraction and Concentration Production Line

Product Application:

Composed by: extractor, filter, pump, heater, evaporator, condenser, cooler, oil separator and project control computer.

After dipping and heating, the liquid of traditional Chinese medicine will be pumped into the external heater for heating from the bottom of extracting tank.

The extra pump liquid will enter into heater for heating from the bottom of the extracting tank to reflow and play its partial mixing effect. After the extracting liquid is heated by the heater, it will be evaporated instantly and separated by the separation concentrator.

The twice steam will enter into the extracting tank, transmitting the heat to the solvent in the extracting tank, and also playing mixing effect.

The residual air will enter into the condenser and become solvent, and after reflux it will enter into the extracting tank. It will enter into the heater for condensed liquid to carry out heat exchange and make the temperature of condensed liquid approximate to the boiling point of solution in the extracting tank.

Then the residual air will enter into condenser. As the solvent has large reflux quantity, the density of solute will be rapidly dissolved The extraction and concentration are synchronous with continuous discharge of concentrated liquid, thus, the process is greatly reduced and only requires 4~6 hours.

Technology and parameter:

| Model | LTN10/4000 |

| The volume of extracting (m³) | 10 |

| Concentrating quantity(kg/h) | 4000 |

| Raw Material Input Capacity (kg) | 1000-1300 |

| Capacity of Concentrating Evaporator | 4000kg/hour |

| Water Circulation Capacity | 300-400T |

| The time of extraction (h) | 8 |

| Concentrate density (%) | 1.2-1.35 |

| The work temperature of extracting and concentrating (°C) | Water: 50-90°C Alcohol: 40-80°C |

| Power of Vacuum Pump | 37kw |

The equipment is also applicable to the extraction and condensation of natural condiments and food additives concerning animals and halobios.

![]()

Q: What price terms you offer?

A: We can offer FOB, FCA, CFR, CIF, EXW and other price terms based on your request.

Q: What payment terms you take?

A: TT, LC, other terms are also workable.

Q: Will you help with installation and stuff training?

A: Yes, we can send our engineers to your place to guide the installation and train your workers if you need, but the buyer should bear our technician's round tickets, accomodation, food and subsidiary USD100/day.

Q: How can I visit your factory?

A: Our factory is located in Ruian city Zhejiang Province. Just let us know your scheduel in advance and we will arrange everything for you!

Any other doubts about our machine, please feel easy to contact with us.

- Tel

- *Title

- *Content

- Tel

- *Title

- *Content