LTSP-50 Automatic Hemp Essential Oil Short Path Molecular Distillation Equipment

LTSP-50 Automatic Hemp Essential Oil Short Path Molecular Distillation Equipment

| Categories | Extracting and Concentrating Machine |

|---|---|

| Brand | LTPM CHINA |

| Model | LTSP-50 |

| Model | LTSP-50 |

| Evaporation Area m2 | 15 |

| Feeding Rate L/h | 200-500 |

| Feeding Method | High-precision gear pump |

| Receiving Method | Continuous discharge pump |

| Equipment Height(mm) | 7500 |

| Max Speed(rpm) | 50-350 |

| Operation Temperature | Up to 350C |

| Vacuum Level(mbar) | Low to 0.001 mbar |

| Feeding Mode | Gear pump for automatic and continuous feeding |

| Unit Price | US $ 95000-100000 / piece |

| FOB port | Ningbo |

| Terms of Payment | L/C, D/A, D/P, Western Union, MoneyGram, T/T, Paypal |

| Update Time | Apr 17,2025 |

LTSP-5 Hemp CBD Oil Short Path Extractor Distillation Equipment

LTSP-50 Automatic Hemp Essential Oil Short Path Molecular Distillation Equipment

Brief Introduction:

LTPM CHINA molecular distillation, also called molecular distiller, it is a process of separation, purification and concentration of natural products, complex and thermally sensitive molecules for example vitamins and polyunsaturated fatty acids.

Molecular Distillation is a special liquid-liquid separation technology, which is different from traditional distillation on the difference boiling point. This is a kind of distillation in high vacuum environment, for the difference of material molecular movement free path, was carried out in the heat sensitive materialor high boiing point material distillation and purification process. Short Path Distillation is mainly used in chemical, pharmaceutical, petrochemical,spices, plastics, oil and otherfields.

Features of Molecular distillation

1. Evaporation efficiency is very high, can reduce retention time, with minimal time delay.

2. Molecular distillation system is composed of high borosilicate glass 3.3, 316L stainless steel and PTFE, so it has excellent anti-corrosion ability.

3. The main part of the molecular distillation system is made of high borosilicate glass 3.3, and the whole operation process can be well observed.

4. The high precision distillation cylinder body enables the liquid to form a complete integrated film on the heating surface.The inner wall of the barrel body is smooth and bright, not easy to stick to the material and scaling.

5. Imported brand variable frequency speed reduction motor,safe and reliable in operation;equipped with self-cooling fan,it can continuous working for a long time.

6. The magnetic drive system makes it possible to seal the whole machine.the transfer bar of the drive motor does not need to pass through the main distiller.the whole set of the distillation system possess good sealability.The min vacuum pressure can reach 0.001mba.

7. The max temperature of the equipment can up to 250℃/300℃ ,accurate temperature control can achieved.

8. Maximum the theroretical vacuum degree can up to 0.05 mbar or 0.001mbar.(secondary diffusion pump is needed)

9. You can free choose of scraper film forming system and self-cleaning roller system.

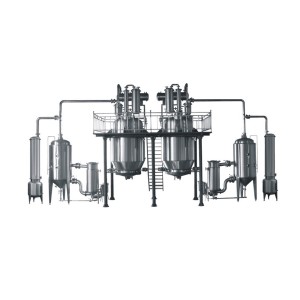

Structure Display:

Technical Data:

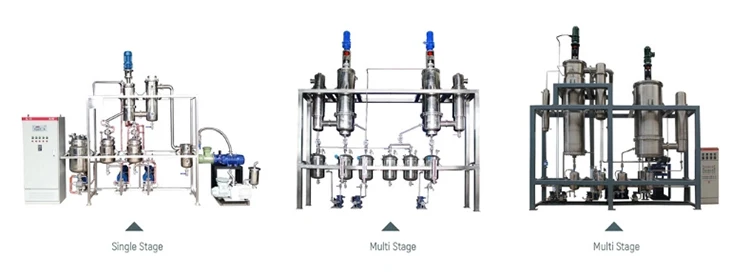

Turnkey Solution for Stainless Steel Molecular Distillation | ||||||||

Model | LTSP-1 | LTSP-2 | LTSP-5 | LTSP-10 | LTSP-15 | LTSP-20 | LTSP-30 | LTSP-50 |

Evaporation Area m2 | 0.1 | 0.2 | 0.5 | 1 | 1.5 | 2 | 3 | 5 |

Feeding Rate L/h | 1-15 | 5-25 | 10-60 | 50-120 | 60-180 | 100-200 | 100-300 | 200-500 |

Feeding Method | High-precision gear pump | |||||||

Receiving Method | Continuous discharge pump | |||||||

Equipment Height(mm) | 2100 | 2650 | 3100 | 4250 | 4500 | 5000 | 6200 | 7500 |

Max Speed(rpm) | 50-350 | |||||||

Operation Temperature | Up to 350C | |||||||

Vacuum Level(mbar) | Low to 0.001 mbar | |||||||

Feeding Mode | Gear pump for automatic and continuous feeding | |||||||

Collection Mode | Gear pump for automatic and continuous collection | |||||||

Details Decide Everything:

Client Case:

Application in Plants Oil Distillation:

Certificate:

Our Customers:

Exhibitions:

1.we have seven technicians who gets passport ready to travel all over world to offer service to you.

2.We have 24hours hot line for Technical Support.

3.We get 18hours internet line for technical support.

4.Video camera in workshop to help you adjust and solve machine problem in working situation.

If you are interested in our machine, please feel free to contact us!

- Tel

- *Title

- *Content

- Tel

- *Title

- *Content