News Group

Industry news

- What should be done if the pressed tablets can not be disintegrated within the prescribed time limitIn the production process of the tablet press machine, there are often cases where the compressed tablets cannot be disintegrated within the prescribed time limit, which affects the dissolution, absorption and efficacy of the drug. What is going on? How to solve it?Aug 26,2020

- High speed mixing granulator how to reduce heat loss? try this optimization!In the production of solid preparation tablets, mixing and granulation are the key to determine the quality of compression tablets or capsules. In a sense, granulation is the key basis. In the past, wet granulation equipment was widely used in the industry, but now wet granulation equipment has developed to high-speed mixing granulator, which is a kind of solid preparation pharmaceutical equipment which develops rapidly in recent years.Aug 18,2020

- What aspects should be paid attention to to build a clean medical workshop?The pharmaceutical industry is a high-pollution industry. In recent years, with the advancement of environmental protection policies, there are not a few pharmaceutical companies that have "slopped" on environmental issues. Due to the difficulty and high cost of pollution control. At present, how to solve the problem of economic and environmental benefits has become a topic that pharmaceutical companies have to face.Aug 3,2020

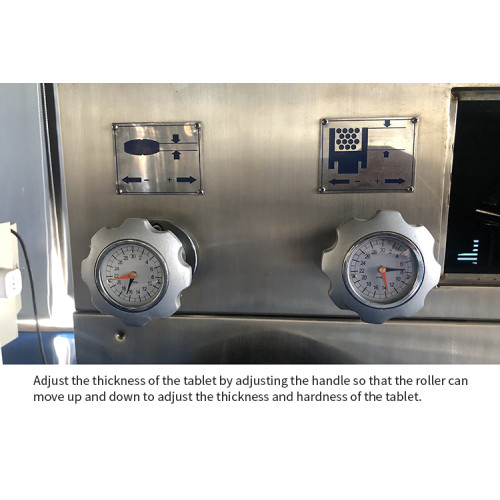

- How to debug the medicine tablet machine Three simple tutorials are worth referring toThe tablet press is a machine that puts granular or powdery materials in the die hole and presses them into tablets.Jul 30,2020

- How to improve the coating success rate is the keyThe purpose of coating is to improve the appearance of the tablet, prevent moisture, avoid light, cover up bitterness or unpleasant odor, and control the release location and release rate of the drug.Jul 30,2020

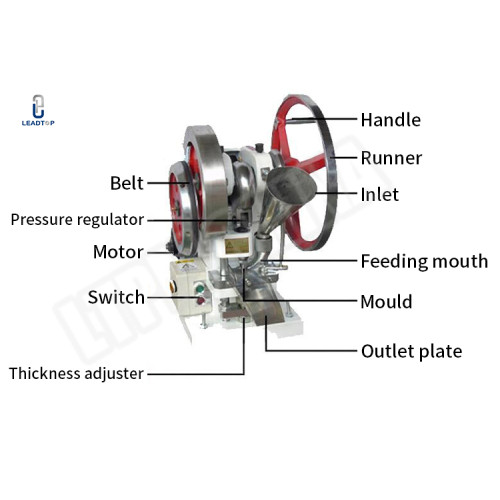

- The use of Single Punch Tablet Press, these maintenance knowledge is essentialIn the pharmaceutical industry, the single punch tablet machine can be said to be an indispensable processing equipment, usually used to compress various Chinese medicine tablets, western medicine tablets, etc.Jul 30,2020

- How to choose the mixer to achieve the expected mixing effectIn the process of medicine and other industrial production, mixer is a common equipment. Its function is to mix two or more materials evenly. In recent years, with the rapid development of pharmaceutical industry, mixer equipment also ushered in the objective market prospects. At present, three-dimensional mixer and two-dimensional mixer are common in the market.Jul 30,2020

- What are the advantages and disadvantages of the three common extrusion granulators?Granulation refers to the operation of processing materials in the state of powder, melt, aqueous solution, etc. into granules with a certain shape and size. At present, the granulation processes used by pharmaceutical companies include extrusion granulation and shear granulation.Jul 30,2020

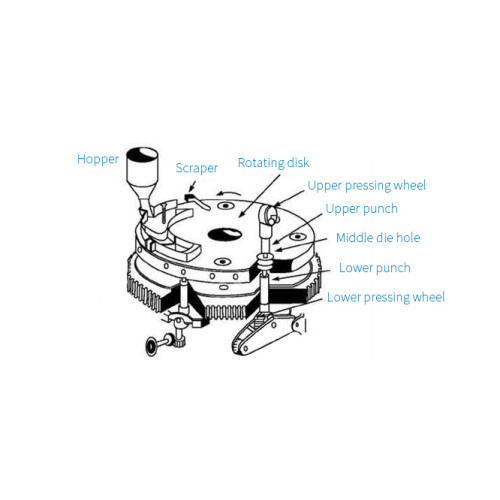

- Regulating mechanism of automatic tablet press machineThe filling dose adjustment on the rotary tablet press is mainly based on the filling rail. By rotating the dial regulating plate, the shaft can be driven to rotate, and the worm shaft connected with it also rotates.Jun 29,2020

- The Selection Of Materials For Effervescent Tablet PressingEffervescent tablet pressing machine is a kind of automatic rotating and continuous tablet pressing machine. It is also a special equipment for chemical, food, electronic and other industrial enterprises to press granular raw materials into tablets or granules, which is suitable for small batch production.Jun 19,2020

- What is a single station tablet press and how does it work?A single station tablet press is a simple mechanical machine that can be used to compress powder into tablets that are uniform in size, shape and weight. The machine is used for low-volume production of tablets for a wide range of applications from cosmetics and pharmaceuticals to cleaning products.Jun 19,2020

- The Different Types Of Tablet Coating MachinesTablet coating machines work on the simple principle of applying the coating ingredients in the form of a solution to a group of tablets in a bed that may move horizontally or vertically. A concurrent flow of heated air helps to evaporate the solvent. The coating is equally distributed to the tablets through the movement of the bed.May 28,2020

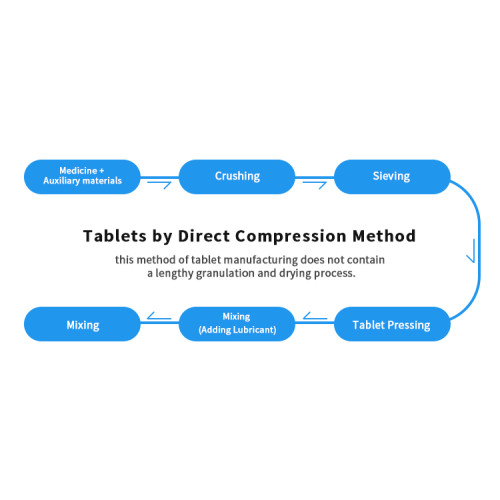

- Manufacturing of Tablets by Direct Compression MethodDirect compression method of tablet manufacturing is widely used because it is a time saving process. this method of tablet manufacturing does not contain a lengthy granulation and drying process.May 26,2020

- World Book and Copyright DayNow more than ever, at a time when globally most schools are closed and people are having to limit time spent out of their homes, the power of books can be leveraged to combat isolation, to reinforce ties between people, and to expand our horizons, while stimulating our minds and creativity.Apr 23,2020

- The Earth DayMother Earth is clearly urging a call to action. Nature is suffering. Australian fires, heat records and the worst locust invasion in Kenya. Now we face COVID -19, a worldwide health pandemic link to the health of our ecosystem.Apr 22,2020

- Orally Dissolving Films (ODFs)The manufacture of orally dissolving films is done by various methods such as solvent casting, hot-melt extrusion, semisolid casting, solid-dispersion extrusion, and rolling. The authors discuss these methods and the various parameters in which dissolving films are evaluated.Apr 10,2020

- Coronavirus disease (COVID-19) advice for the public When and how to use masksCoronavirus disease (COVID-19) advice for the public When and how to use masksMar 30,2020

- Wet Granulation ProcessWet granulation forms by binding the powders together with an adhesive, instead of by compaction. bridges are developed between the particles and the tensile strength of bonds increases as the amount of liquid added is increased.Mar 23,2020

- Types and Functionality of Tablet CoatingDifferent types of tablets need different coating according to the nature and properties of the tablets.Coating of tablets helps to protract the tablets from environmental conditions on the other hand it improves the taste of tablets.Mar 22,2020

- Granulation Process in Pharmaceutical ManufacturingGranulation is the main manufacturing process for the manufacturing of tablets. It is of two types wet and dry that is adopted on the basis of the API used in the manufacturing.Mar 3,2020

- Daily Maintenance Skills Of Tablet Press Machine Mould In Pharmaceutical FieldTablet press belongs to a kind of pharmaceutical processing equipment, which is suitable for tablet pharmaceutical tablet forming. In the process of tablet pharmaceutical production, tablet press mold plays an important role in the quality of products.Dec 13,2019

- GMP Qualifications And Validations In The Pharmaceutical WorldGood manufacturing practice (GMP) is a system for ensuring that products are consistently produced and controlled according to quality standards. It is designed to minimize the risks involved in any pharmaceutical production that cannot be eliminated through testing the final product. Good manufacturing practice guidelines provide guidance for manufacturing, testing, and quality assurance to ensure that a food or drug product is safe for human consumption.Dec 12,2019

- Film Coating Process In The Pharmaceutical IndustryThe coating process is important step in the manufacture of modern pharmaceutical tablets. The coating itself can serve several functions – it can strengthen the tablet, control the release of active ingredients, improve its taste, provide colour, make it easier to package and handle, and protect it from moisture. Sugar coating was one of the earliest methods developed to coat tablets and is still practised for some products, especially confectionery.Dec 4,2019

- Rapid Mix Granulator – Operation and Cleaning GuideA rapid mix granulator is a multi-purpose mixer/processor equally suitable for high speed dispersion of dry powders and their granulation with aqueous or organic solvents. The equipment is designed to achieve rapid mixing and the formation of consistent granules required for the production of high quality pharmaceutical tablets for solid dosage forms of medication. Good mixing and control of granule size leads to fast tableting speeds and high quality products with low rejection rate.Nov 26,2019

- Types of TabletsPharmaceutical tablets may be defined as the solid unit dosage form of one or more medicaments with or without suitable excipients and prepared either by moulding or by compression.Nov 25,2019

- Where Tableting Technology Is HeadingThe tablet making industry is currently going through a period of significant change. An increasing number of patents are expiring giving tool makers and tablet manufacturers plenty of opportunity to innovate in a range of technologies.Nov 22,2019

- Tablet Coating Defects and their RemediesCoating tablets with a thin polymer film can be an effective way to give your products a professional edge. High quality tablets can be quickly and easily produced using a tablet coating machine and the correct excipients . Unfortunately several defects can arise with coatings. The following list provides helpful remedies for common issues that may be encountered.Nov 21,2019

- Spray drying in the pharmaceutical industrySpray drying is one of the most remarkable technologies currently to be applied to pharmaceuticals. It is a continuous process that converts, in a single step, a liquid feed into a powder and is an ideal process when precise attributes such as particle size, morphology and stability are required. This review describes the technology, current and future applications and how the present level of understanding and modeling tools enable a process development stage that is both lean and risk-free.Nov 18,2019

- Application of eight drying equipments in chemical and pharmaceutical industryDrying equipment is very widely used in industry, and the use of drying equipment is needed in many fields. Also, drying equipment also plays an important role in the pharmaceutical industry. Today, the author will bring eight kinds of drying equipment in the chemical and pharmaceutical industry. The application of eight drying equipments in chemical and pharmaceutical industry is analyzed.Nov 15,2019

- Difference between dry granulation and wet granulation-victor granulator?Difference between dry granulation and wet granulation-victor granulator?Nov 14,2019

Please send your message to us

- Tel

- *Title

- *Content

CONTACT US

subscription