News Group

Product news

- High end of pharmaceutical packaging machinery has become a trend, but still faces challengesPharmaceutical packaging machinery has a great impact on the quality and safety of drugs. In recent years, with the rapid development of China's pharmaceutical industry, it has brought good opportunities to the pharmaceutical packaging machinery industry, but at the same time, the requirements of drug quality are constantly improving, and the pharmaceutical packaging equipment is also facing higher requirements.Feb 26,2021

- The way of label breakage of labeling machineIn the process of the rapid development of the pharmaceutical market, labeling machine also plays an increasingly important role in the pharmaceutical packaging industry. At present, the common labeling machines on the market include dry adhesive labeling machine, sleeve labeling machine, round bottle labeling machine, hot melt adhesive self-adhesive labeling machine, etc.Feb 26,2021

- High quality purified water equipment will help the pharmaceutical industry to continuously meet the standards of pharmaceutical waterIn recent years, with the rapid development of the pharmaceutical industry, the quality requirements of pharmaceutical production also began to improve. Affected by this, the pharmaceutical industry's requirements for pharmaceutical equipment for its production are also increasing.Feb 26,2021

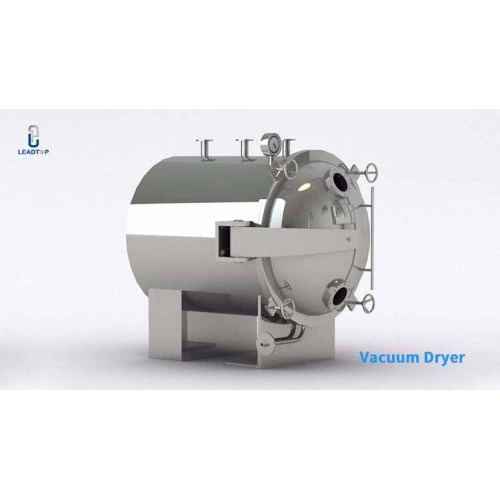

- Application and development prospect of vacuum technology in pharmaceutical machinery industryAccording to the definition, vacuum technology refers to the establishment of a physical environment lower than atmospheric pressure, as well as the technology required for process manufacturing, physical measurement and scientific experiments in this environment. At present, vacuum technology is widely used in pharmaceutical, chemical, food, electronics and other fields.Feb 26,2021

- Hot air circulation oven processing effect is not ideal Take this maintenance strategyHot air circulation oven is a very common oven equipment in the pharmaceutical industry. It uses steam or electricity as the heat source, and uses the axial fan to heat the heat exchanger by convection. When the hot air laminar flows through the drying plate and the material for heat transfer, the fresh air can come in from the air inlet, and the waste hot and humid air is discharged from the wet outlet, and the whole system is constantly replenished through thisFeb 26,2021

- Hot air circulation oven several major maintenance precautions, quickly write downHot air circulation oven is a common equipment in the pharmaceutical industry. In the process of use and maintenance, we must follow the relevant principles and grasp the relevant precautions, so as to ensure the stable operation of the equipment and the smooth drying production process.Jan 19,2021

- A brief introduction to the punch of tablet pressThe tablet press punching die is also the most commonly used tablet equipment tablet press on an indispensable accessory. It is also a very important work to choose the appropriate punching die correctly after the purchase of the tablet press. In many tablet pharmaceutical factories, the tablet press purchased can not be used normally because of the improper selection of the punching die. .Jan 11,2021

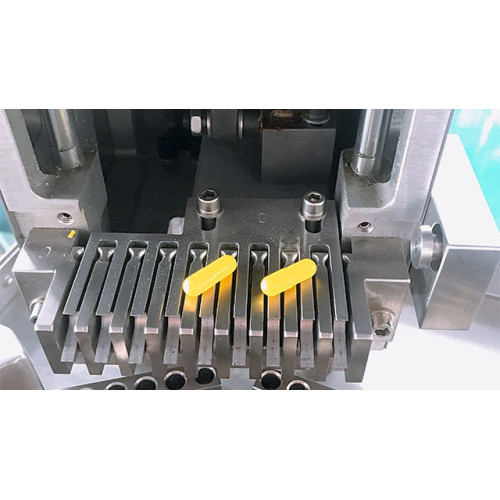

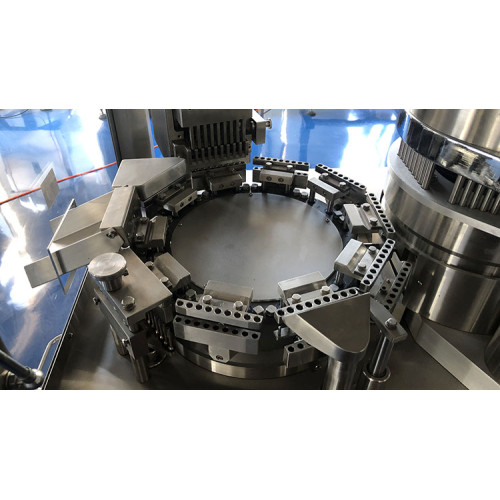

- Operation Specification And Maintenance Method Of Automatic Capsule Filling MachineRegarding the fully automatic capsule filling machine, what operating specifications and maintenance methods we usually need to pay attention to, the following editor will take you to learn more.Dec 3,2020

- How to debug the tablet press? Three simple tutorials are worth referenceThe tablet press is a kind of machine which puts the particles or powder materials in the mold hole and presses them into tablets by punch. It is especially suitable for small batch production. It is characterized by adjustable speed, filling depth of materials, sheet shape thickness and mechanical buffer installed on the machine, which can avoid dust generated during operation, prevent sticking and blocking, and recycle raw materials for reuse.Nov 24,2020

- Advantages and disadvantages of vibrating fluidized bed and energy saving measuresVibrating fluidized bed is a conventional equipment for drying in pharmaceutical industry, which belongs to the type of convective drying. The working mechanism of the flow dryer is that the heat is directly transferred to the wet material by hot air convection, and the water vapor is taken away at the same time when the moisture vaporizes. Besides the dryer itself, the device also has fan, heater, separator and other auxiliary equipment.Oct 28,2020

- spray dryer cleaning and maintenance are fastidious, these commonly used methods must be kept firmly in mind.Spray dryer is a device that can dry and granulate at the same time. It mainly consists of slurry supply system, atomizer, drying tower, hot air system, exhaust gas and dust removal system, unloading and powder conveying system.Sep 16,2020

- How to improve the filling quality of capsule filling machine Pay attention to these stationsIt is reported that some pharmaceutical companies in the process of producing capsules, due to the fine powder, will produce appearance defects during machine filling, which has always been required to remove by manual "drug selection". Through continuous optimization and debugging of the capsule filling equipment, the product rate of appearance defects is reduced, and the labor cost is greatly reduced.Aug 12,2020

- The diversified requirements of the rotary tablet press structure:In the customized orders of users, the diversified requirements for the structure of the tablet press are mainly manifested in the following aspects:Jun 22,2020

- The diversified requirements of the rotary tablet press structure:In the customized orders of users, the diversified requirements for the structure of the tablet press are mainly manifested in the following aspects:Jun 22,2020

- Causes and Remedies of Cracking in Tablet ManufacturingCracking in tablets during the compression is a major problem in tablet manufacturing. Some causes and solutions of the cracking of tablets are given here.May 25,2020

- Structure and principle of capsule filling MachineThe filling speed of capsule filling machine is faster and the size difference of capsule filling machine is small. In addition, capsule filling machine has many advantages, such as fast arrangement speed, high efficiency, simple operation, convenient maintenance, low power consumption and so on. It is the first choice capsule filling machine for pharmaceutical factory, health product factory, hospital preparation room.May 25,2020

- Daily Maintenance And Common Failure Analysis Of Capsule Filling MachineIn the pharmaceutical industry, the capsule filling machine is a kind of commonly used equipment, which can carry out automatic transmission, seeding, filling, locking and other processes for capsules.May 12,2020

- Common faults and solutions of tablet press machineCommon faults and solutions of tablet press machineApr 26,2020

- The Most Complete Solution To Sticking And Punching Of Tablet Press MachineIn the process of pressing, there are often problems such as sticking and punching. When pressing the tablet, the fine powder on the surface of the tablet is adhered by the punch or die, but the surface is not smooth, uneven and dented. The inspection punch often has the fine powder sticking, which is called stick punching.Apr 21,2020

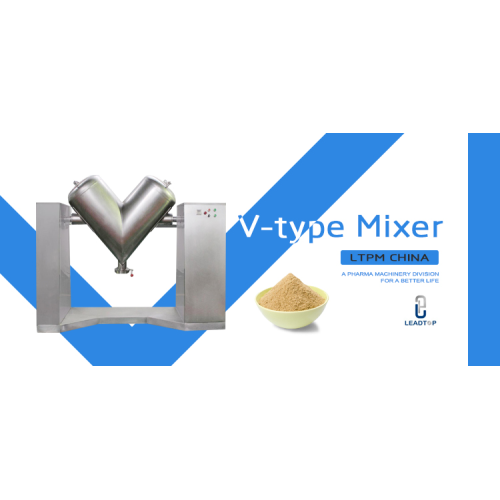

- Importance of Mixing Time in Blend UniformityImportance of mixing time and effects of extended mixing time on blend uniformity and pharmaceutical product quality.Mar 17,2020

- Storage And Maintenance Of Powder Tablet Press MouldIn the pharmaceutical production process, the molds used for tablet pressing play a vital role in the quality of tablets. The length of impact body is different, which directly affects the weight difference and hardness of tablet, or affects the brittleness; Punch edge knock edge or punch is not flat, the impact of one - sided caused by split, stick and so on.Jan 9,2020

- Problems And Solutions In Tablet Coating ProcessThe coating process of sugar-coated tablets is complex, time-consuming and prone to many problems, such as cracks, bare edges, hemp noodles, patches and so on. Sugar coating has gradually been replaced by film coating, the following is only the film coating problem.Dec 31,2019

- Main Factors Affecting The Production Quality Of Automatic Capsule Filling MachineThere are many factors that affect the quality of the automatic capsule filling machine, among which the powder filling mechanism and the positions of the capsule turret are important factors. In the aspect of powder filling mechanism, the powder filling mechanism is mainly composed of 6 equal parts of intermittent rotary movement metering plate, 6 groups of axial movement punch rod (adjustable axial position) and powder screw automatic feeder.Dec 26,2019

- Disassembly And Installation Of Main Parts Of Small Powder Tablet PressDisassembly And Installation Of Main Parts Of Small Powder Tablet PressDec 25,2019

- Operation Flow Of Capsule MachineCapsule filling machine integrates machine, electricity and gas. It adopts micro-computer programmable controller, touch panel operation, frequency conversion speed regulation, equipped with electronic automatic counting device, which can automatically complete the capsule positioning, separation, filling, locking and other actions, reduce labor intensity, improve production efficiency, and meet the requirements of pharmaceutical hygiene.Dec 24,2019

- Installation Of Punch Die For Core Device Of Tablet Press MachinePharmaceutical tablet press is good or bad has a most reason is determined by the punching machine, in a nutshell is the punching machine is the core of the tablet press device, whether any form of tablet press, such as tablet tablet machine, high speed tableting machine, double tablet machine, double tablet machine, circular piece of tablet press, candy tablet press, etc., all need to be aware of is the installation of punching die!Dec 23,2019

- Regular maintenance of tablet pressCheck the machine parts regularly, 1-2 times a month. The inspection items are whether the worm wheel, worm, bearing, pressing wheel, crankshaft, upper and lower rail guide and other moving parts rotate flexibly and wear. If any defect is found, it shall be repaired and used in time.Dec 17,2019

- How To Deal With The Increase Of Slice Weight Difference In High Speed Tablet Press MachineTablets are solid preparations made of tablets or special-shaped tablets after evenly mixed with drugs and excipients. Because they are simple to take and easy to carry, the market size of tablets has been growing continuously in recent years. The management and treatment of these common diseases, frequently-occurring diseases and chronic diseases are closely related to the use of tablets.Dec 16,2019

- Structure Of Automatic Capsule Filling MachineThe fully automatic capsule filling machine consists of an empty capsule discharge device, a capsule distribution device, a powder discharge device, a metering plate mechanism, a capsule filling and sealing mechanism, a box main drive mechanism, and an electrical electrical control system.Dec 11,2019

- Maintenance Of Automatic Hard Capsule Filling Machinewhen the machine works normally for a long time, the parts that are in direct contact with the drug should be cleaned regularly. When the drug batch is changed or the time of withdrawal is long, the parts should be cleaned regularly.Dec 10,2019

Please send your message to us

- Tel

- *Title

- *Content

CONTACT US

subscription