How to improve the production efficiency of the labeling machine and reduce the cost? Maintenance skills are essential

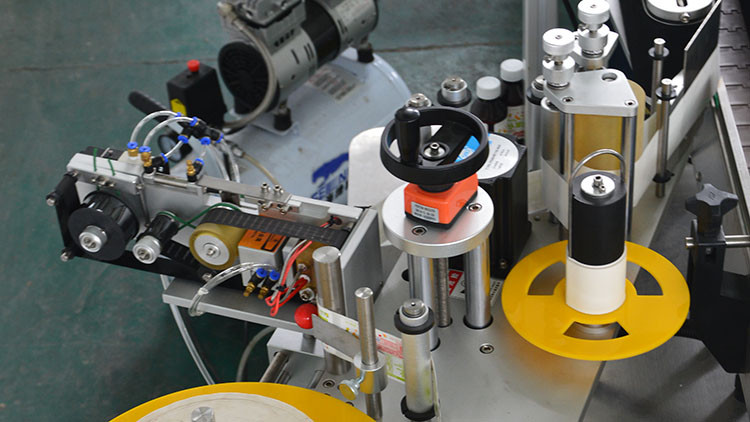

In the pharmaceutical industry, the labeling machine is a very common packaging equipment. Its main function is to label the products to meet the market's packaging requirements for pharmaceutical products. According to different adhesive coating methods, labeling machines can be divided into: self-adhesive labeling machine, paste labeling machine (adhesive labeling machine, glue labeling machine) and hot melt adhesive labeling machine; According to different types of products, it can be divided into: linear labeling machine, rotary labeling machine, etc.; according to the realization of different labeling functions, it can be divided into: flat labeling machine, side labeling machine and circumferential labeling machine; In addition, according to the degree of automation, it can be divided into: automatic, automatic, semi-automatic and manual labeling machines.

The application range of different types of labeling machines is different. For example, the flat type labeling machine realizes the labeling and filming on the upper plane and the upper arc surface of the workpiece, such as boxes, books, plastic shells, etc.; round bottle labeling machines mainly Achieve labeling or filming on the circumferential surface of cylindrical and conical products, such as glass medicine bottles, plastic bottles, etc.; side labeling machines mainly realize labeling or filming on the side plane and side arc surface of the workpiece, such as cosmetic flat Bottles, square boxes, etc.

Regardless of the labeling machine, the user spends a lot of money to purchase the purpose is to improve production efficiency, reduce costs, and reduce the error rate of manual labeling. However, in actual operation, users not only need to master the correct use method, but also need to understand the maintenance skills of the labeling machine in order to maintain the long-term stable operation of the equipment, make the equipment more effective, and delay the service life of the equipment. Two aspects were introduced by the manufacturer's technicians.

On the one hand, users must pay attention to cleaning when maintaining the labeling machine. Since the labeling machine is easy to inhale dust during operation, it is necessary to clean the dust on the labeling machine regularly.

If the user is not using the labeling machine temporarily, he should unplug the power supply and cover it with a dust-proof cloth to prevent dust from falling on the labeling machine. In addition, the high temperature belt of the labeling machine also needs to be decontaminated regularly, so as to better ensure the high-quality operation of the labeling machine.

For some labeling machines that are malfunctioning, the cleaning work needs to pay more attention to details. For example, when a user uses an automatic labeling machine, if the automatic labeling machine is not perpendicular to the desktop, it means that the coding effect is very poor. In addition, it is recommended to use the cleaning box to clean the machine when cleaning, to clean the ink in the pipe and the nozzle, otherwise the ink will block the nozzle; if there is a leakage phenomenon during the printing process, it is necessary to check whether the inkjet printer has an eye Damaged, and clean the sensor head, adjust the sensor’s sensitivity point, check the sensor’s installation and fixation conditions, adjust the sensor’s installation position, and eliminate the influence of the surface color of the object on the sensor’s induction.

On the other hand, the labeling machine needs maintenance after working for a period of time, especially remember to apply lubricating oil. It is understood that there are many parts in the labeling machine, such as gears, bearings, and gearboxes. These parts are very easy to rust or wear after being used for a period of time. The lubricating oil can ensure the smoothness of all parts of the labeling machine. The technician pointed out that under normal circumstances, the labeling machine should be lubricated after working continuously for more than 48 hours.

The life extension of any equipment is inseparable from careful maintenance. The labeling machine should be regularly maintained after it has been in operation for a certain period of time, so as to ensure that the labeling machine operates well, and at the same time, it can extend the life of the labeling machine and ensure that the labeling machine can operate normally.