Extraction and Concentration Machine Effectively Removes Impurities in Medicinal Herbal and Improves the Stability of Preparations

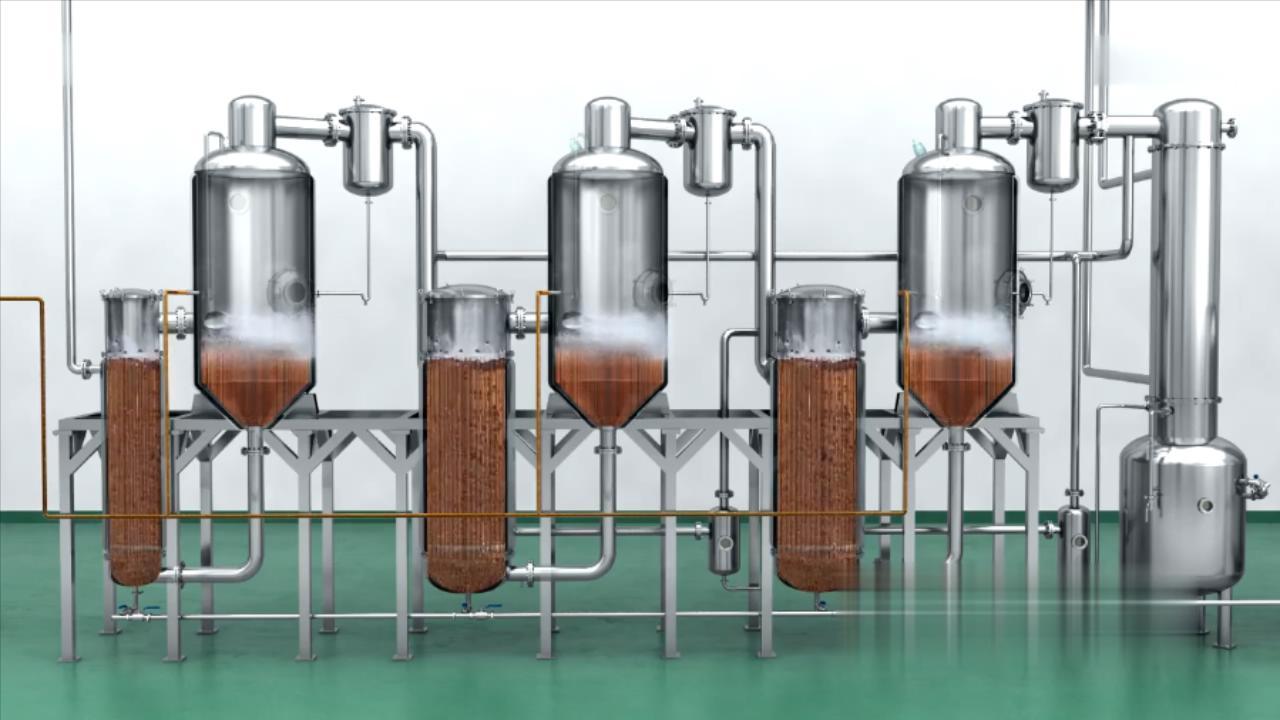

Extraction and concentration is extremely important in the Natural Herbal medicine industry. With the steady improvement of extraction and concentration technology, the market for extraction and concentration machines has become larger and larger. Not only has the equipment type increased, but many new types of extraction and concentration machines have gradually emerged.

Specifically, during the extraction process of the Natural Herbal medicine extracting and concentrating machine, the hot solvent will continuously increase on the surface of the medicine, pass through the medicinal material layer at high speed from top to bottom, and then dissolve the solvent in the medicinal material. The solution content in the medicinal materials and the solution content in the solvent maintain a high gradient until it is completely dissolved. The extraction rate of effective ingredients is high, and the yield of concentration paste is high, and the content of effective ingredients in the ointment is also high.

According to some manufacturers, the extraction concentrator is suitable for atmospheric pressure, micro pressure, water decocting, warm soaking, heat reflux, penetration, extraction of aromatic oil components, and recovery of organic solvents in Natural Herbal medicine, plants, food, beverages, and chemical industries.

Because Natural Herbal medicine contains complex chemical components, there are usually sugars, amino acids, proteins, oils, waxes, enzymes, pigments, vitamins, organic acids, tannins, inorganic salts, volatile oils, alkaloids, glycosides, etc. These ingredients have both effective ingredients and ineffective impurities. If the impurities are not removed as much as possible, the quality and stability of the preparation will be affected. Therefore, the Natural Herbal medicine extraction concentration machine is very important.

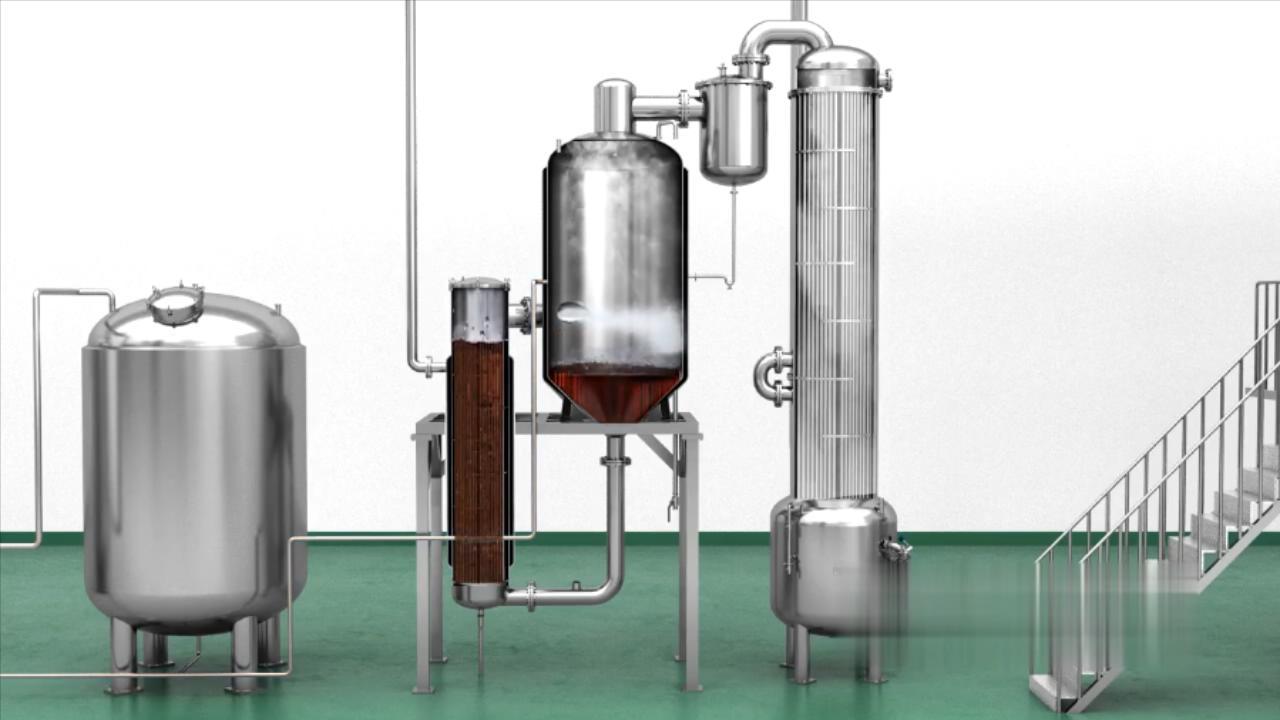

The author has learned that the extraction and concentrator currently used in the production of Natural Herbal medicine not only has a small footprint, is exquisitely produced, and has complete supporting facilities, but is also very convenient to operate. It is more suitable for small batches and multi-variety production methods. The equipment has complete functions and is suitable for water extraction and alcohol extraction. It can carry out atmospheric and negative pressure extraction and can recover volatile oil.

In addition, the equipment is also equipped with a vacuum converter and a control box, which is easy to operate, and can achieve normal temperature extraction and low temperature concentration; normal temperature extraction and normal temperature concentration; low temperature extraction and low temperature concentration and other process requirements.

"The electric heating structure of the extraction and concentration machine is advanced, safe, fast heating and cooling, and even heating. The tank is equipped with a safety decompression device to ensure safe use." The manufacturer said that the reflux extraction process can be realized, reducing the extraction and concentration time and saving Solvent. The unique oil-water separator design integrates the vacuum conversion function to make the oil-water separation effect better. The equipment is made of glass for easy observation.

Experts remind that there are some things to pay attention to when using the Natural Herbal medicine extraction and concentrator. Take the heat recirculation unit as an example, 4 points need to be paid attention to when using the heat recirculation unit. To determine the amount of medicinal materials in each tank through verification, the principle of heat reflux extraction determines that the amount of material is larger than that of the multifunctional extraction tank.

Second, determine the time to start reflux according to the concentration of the chemical solution. If the reflux time is too early and the concentration of the extract is low, the effective extraction time will be prolonged. If the reflux time is too late, the saturation of the extract is not conducive to the extraction of active ingredients and wastes energy.

"One hour after the extraction (boiling), part of the liquid medicine should be put into the concentration tank, and the reflux and timing should be started. Note that the air in the tank should be removed when the extraction tank is boiling, otherwise pressure will be generated in the tank." Experts said.

Third, the temperature of the reflux liquid must be controlled and not too low. At the same time, it is necessary to control the temperature in the extraction tank and try to maintain a constant temperature. Cold extraction (below 90℃) has less impurities, good clarity, high heat extraction efficiency, and poor clarity.

The purpose of boiling is to enhance the diffusion and penetration of the solution. Boiling Ruiran can reduce the concentration difference of the solution in a short time, but it will dissolve many macromolecular impurities.

Fourth, determine the extraction and concentration time. Excessive extraction will increase the impurities in the extraction solution and make the later separation more difficult. If the time is too short, the extraction will be incomplete, and the raw materials will be wasted (the solution concentration needs to be checked during the extraction process).