Causes of asymmetry of V Blender and correct operation

Due to the excellent performance of the V Blender and the relatively complex system parameters, if non-professionals do not understand it, it is easy to have some failures in early use, such as asymmetry when using the V Blender, then the mixing work What is the reason for the asymmetry of the V Blender? Then, how should we operate the V Blender? Below, I will briefly introduce you how to do the operation on V blender and maintenance on V Blender.

Reasons for asymmetry of V Blender:

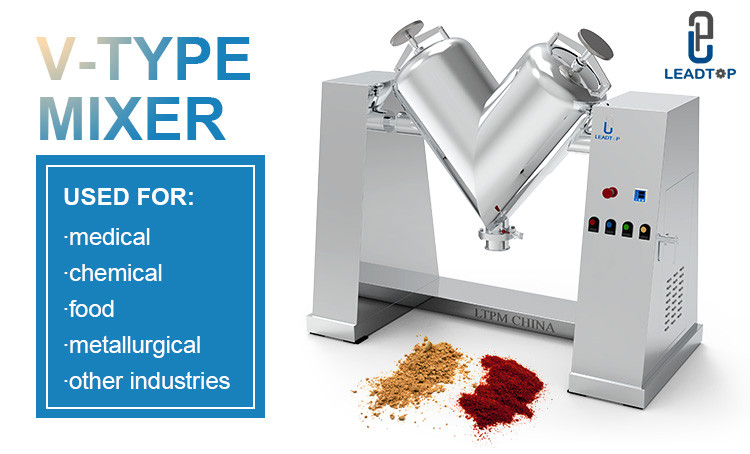

The V Blender mixing barrel is two asymmetrical cylinders, made of δ3mm304 or SS316L high-quality stainless steel plate circle and formed by round and close welding. Facilitate the cleaning of the cylinder body after the material is mixed.

The V Blender transmission system is composed of motor, reducer, sprocket, bearing, transmission shaft and other parts. The transmission shaft is fixedly welded on the cylinder wall and reinforced with δ5.0mm steel plate. There is no jitter, no eccentricity, and low noise during the working process. Convenient maintenance, long service life, stable operation and other characteristics.

The frame of V Type Mixing Machine is made of channel steel welding, which is welded firmly, and the frame is made of 304 stainless steel, and the surface is flat and scratch-free. The two ends of the transmission frame are movable doors, which are convenient for maintenance and repair.

Electrically controlled and sensitive. The mixing time is controlled by a digital display time relay. The mixing time of V blender is set according to the requirements of the actual production process of the mixing. The inching button is used to move the cylinder to the appropriate loading position or discharging position, and the material is in and out. . Reduce labor intensity and improve production efficiency.

Correct operation of V Blender:

In the case of conveying materials, open the feed port of V Mixing Machine, close the discharge port according to the technical control requirements, and put a certain amount of material into the V Blender loading hopper. At the end of the feed, in order to prevent the material from flowing out during mixing, the feed port must be closed and locked.

During machine operation time, turn on the power button, turn the stop button to the left, start V Type Mixer reverse button, and adjust the motor speed within the speed range specified in the technical rules to mix the cargo at 3-12R/min. When the mixed materil reaches the technical rules, after the speed button of the conditioning motor stops, the discharge port of the mixer should face the ground, and the speed button of the adjustment motor should be adjusted to 0 position v agitator. Rotate the stop button to the right to block the power supply .

On end of the V Blender is equipped with a motor and a reducer. The power of the motor is transmitted to the reducer through a belt, and then the reducer is transmitted to the V barrel through a coupling. The V-shaped barrels are operated one by one, and the materials in the moving barrel are mixed, down, left and right mixed in the barrel.

The V-shaped mixer organizes the moving cylinder by decelerating the rotation, and uses the asymmetry formed by the unequal length of the two cylinders of the mixer for mixing. When the mixer moves, due to the difference in potential energy, the material changes from differentiation to combination. Due to the difference in potential energy, a lateral force is generated to promote the horizontal transfer of the material. When materials change from combination to differentiation, due to different material levels, lateral forces are generated to promote the horizontal transfer of materials.