Wet Granulation Process

Wet granulation forms by binding the powders together with an adhesive, instead of by compaction. bridges are developed between the particles and the tensile strength of bonds increases as the amount of liquid added is increased.

Wet granulation involves the massing of a mix of dry primary powder particles using a granulating fluid.The fluid contains a solvent which can be removed by drying, and should be non-toxic.Typical solvents include water, ethanol and isopropanol and methylene chloride either alone or in combination. The granulation liquid may be used alone or, more usually, as a solvent containing a dissolved binder / suspension / gelatinized binder. (also referred to as a binder or binding agent) which is used to ensure particle adhesion once the granule is dry.

Granulating liquids may be used alone or with dissolved binders (glue)

Solvent (e.g. Ethanol, Isopropanol)

-better for moisture sensitive products

-volatile and so they evaporate/dry more quickly

-can be expensive to purchase

-environmentally responsible disposal can be expensive (solvent recovery plant)

Aqueous (Water)

-cheaper

-safer to handle (non-flammable)

-easier to handle and dispose of in an environmentally responsible manner

-can adversely affect stability by hydrolyzing susceptible products

-longer drying times (and so longer exposure to heat and abrasion)

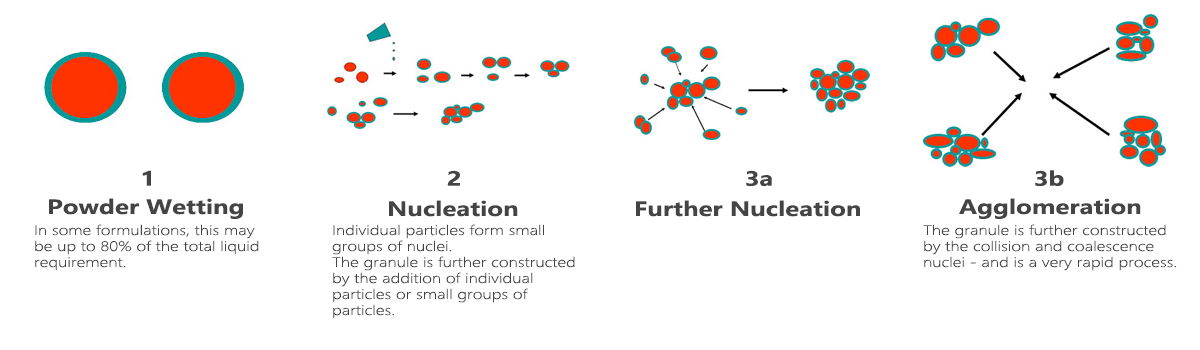

Wet Granulation - the Process

For most products, the wet granulation process has three parts

1. Powder Wetting

2. Nucleation

3. Further nucleation or Agglomeration

As the granulation cycle progresses:

-the mean particle size increases

-the particle size distribution narrows

-the granules become more spherical

-density increases

-porosity decreases

1. Powder Wetting

In some formulations, this may be up to 80% of the total liquid requirement.

2. Nucleation

Individual particles form small groups of nuclei.

The granule is further constructed by the addition of individual particles or small groups of particles.

3a Further Nucleation

3b Agglomeration

The granule is further constructed by the collision and coalescence nuclei - and is a very rapid process.

Powders

-particle size

-substrate solubility

-wettability

Binder

-added as dry powder or in dissolved in granulating liquid

-amount of binder

-rate of addition and method (sprayed, poured)

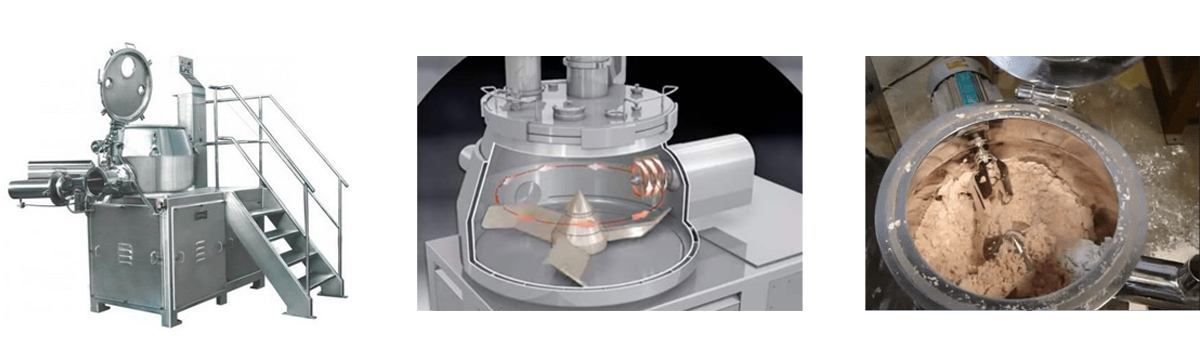

Types of Wet Granulators

Granulation carried out using Planetary Mixer

Granulation carried out using Rapid mixer granulator (RMG).

Granulation carried out using single pot processor.

Type of Equipment

-slow speed / high speed mixer / granulator

-wet mill / dry mill required? screen size?

Drying:

Tray Drying Ovens (several hours)

-Older technology (similar to baker’s ovens) with a lot of manual manipulation

-liquid can only be lost from the upper surface of the granule packed in the tray.

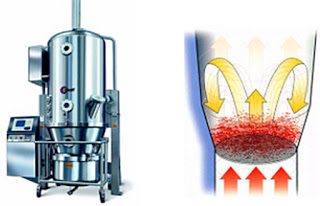

Fluid Bed Dryers (tens of minutes)

-fine mesh at the base and cloth filter bags at the top prevent granule escaping

-warm, dehumidified air is passed up through the base at such a force that it fluidizes the granules

-the liquid can be lost from a much greater surface area and so drying times are shortened

-movement of granules may lead to attrition

Microwave / Vacuum Dryers (tens of minutes)

-often used in “single pot” equipment (granulate and dry in the same vessel)

-maximum batch size is limited to allow penetration of the radiation

-gives rapid drying with relatively low temperatures

-the granule is stationary so less attrition.

The milling used during the granulation stages can be defined as:

Milling / Screening / Sizing

Wet Milling - directly after the mixer granulator and before the dryer

Dry Milling - directly after the dryer

The mills used are to break down lumps or agglomerates by screening and not for high energy size reduction

This helps to give a more uniform granule size

A typical mill for wet or dry milling would be a Comil. The impeller blade is not in contact with the screen but it “pushes” the granule through when it rotates.

Preparation of Binder

-Steam kettle must be cleaned as per the relevant cleaning SOP.

-Cleanliness must be checked and recorded by the Production Officer on batch manufacturing record.

-Line clearance must be done and documented as per relevant SOP.

-Binder material of only one lot should be brought to the binder preparation area.

-The Steam kettle should be operated as per relevant SOP.

-SS accessories should be cleaned as per relevant SOP.

-Code No. of stainless steel sieve to be recorded in BMR

-The steam kettle must have status label at all times.

-The exhaust of binder area must be kept `ON' during the preparation of binder.

-Calibration of steam kettle pressure gauges and pressure testing should be done every year.

-Whenever stirrer is used for binder preparation, ensure that it is not touching to the bottom of the steam kettle.

Planetary Mixer

The planetary mixer is used for wet mixing of the powders, Powder mixing usually has to be performed as a separate operation using suitable mixing equipment. The mixed powders are fed into the bowl of the planetary mixer and granulating liquid is added as the paddle of the mixer is responsible for wet mixing and kneading action required to form the granules. The paddle of the planetary mixer has planetary motion. Design of mixer is such that there is a bare minimum clearance between the wall of mixer and blades and devoid of any void spaces.

Granule Lubrication

-After drying and before compression a lubricant is added and the granule is blended for a short time (the lubrication blend).

-The lubricant forms low strength bonds on the surface of the granules which helps flow and prevents the granules sticking to the compression punches.

-It also helps prevent the tablet sticking in the die and assists in tablet ejection.

-The most common lubricant is Magnesium stearate.

High-Speed Mixer-Granulator

The machines have a stainless steel mixing bowl containing the main impeller, which revolves in the horizontal

plane, and an auxiliary chopper (breaker blade) which revolves either in the vertical or the horizontal plane.

Safety precautions to be taken during operation and machine changeover.

-Compressed air must not be less than 1.5 kg/cm2

-Before scrapping the material ensure that the agitator blade and chopper are not in motion.

-During the changeover, the electrical panel board, PLC and an electrical motor for the chopper, motor for lifting and positioning device must be covered with polybag.

-During washing and scrapping of the equipment, the main switch must be off.

-The operator should not insert hand in discharge port during unloading of wet granules.

-Nuts and bolts must be checked before starting the operation.

-During manual checking of endpoint during granulation ensure that motion of agitator and chopper are stopped completely.

-Never bypass any safety interlock to operate the machine.

-Never touch the moving parts of the machine.

-Do not hold the saizoner lid without locking rod.

-Check for any unwanted material inside the bowl.

-Do not insert hand in discharge port during unloading the granules.

-5 m filter of the respective product to be fixed to the air vent of saizoner mixer.

-Calibration of agitator and chopper should be done once in six months.

-Calibration of pressure gauge should be done every year.

Fluid Bed Dryer

1.The advantage of Fluid Bed Granulator.

-Rapid wet massing, agglomeration and drying is carried out in within one unit.

-Granulation operation is less laborious and time-consuming as compared to other types of wet granulators.

2.Disadvantages of Fluid Bed Granulator.

-No adequate mixing of powder components.

-There is the tendency of demixing especially when there is disparities in particle size and density in the material being processed.

-Particles under granulation have tendency to stick to the equipment filters this reduces effective filter surface area. This also causes product loss and increase in cleanup difficulties.

The author is Ankur Choudhary

Ankur Choudhary is India's first professional pharmaceutical blogger, author and founder of Pharmaceutical Guidelines